Are you curious about how we make your pleated filter cartridge?

JD Filtration has 3 pleated production lines, 4 welding machines with a production capacity of 5000 pcs per day. Pleated technology is a great method that increases filtration area. With this technology, you will get various types of filters.

1. Making cartridge Pleats

Making cartridge pleats starts from putting quality lab tested filtration media with suitable width on a roller. Pleating machine starts making 20-30 pleats as trial running to adjust pleating speed and pleat height. Trial running is important for pleats to have firm structure, be tough and strong. Then in formal running, pleats are made and the cutter of the pleating machine is set to cut off a certain length of pleated membrane. One worker will gather the pleated membrane into a box and forward to next procedure.

2.Side Seam Thermal Welding

Thermal welding is also known as side seam sealing of pleated membrane. We use Ultrasonic welding machine, which ensures 100% integrity of side seam. And without any additives, our thermal welded pleated filter cartridge will have less unwanted extractable in filtration process.

3.Length Control Unit

Length control unit is needed to make sure the length of pleated membrane is correct for the ordered length. Take 10” pleated filter cartridge for example, we need to cut off the surplus length on both sides of the thermal welded pleated membrane to make sure it is 10” long to fit the cage and end caps. Length control is important for the filter cartridge integrity. Too long or too short, it will end up with leakage and by pass in filtration process.

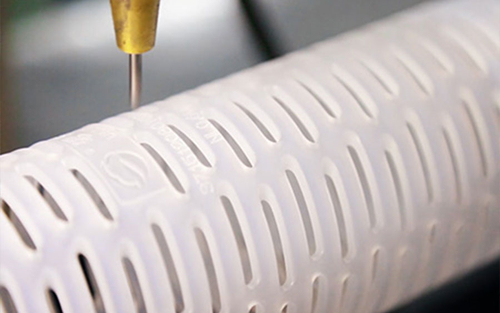

4.Shaping

Shaping means putting the correct length pleated membrane into the outer cage with inner core inside the membrane, to keep the filter cartridge to have initial shape.

5.Flat Cover Thermal Welding

Flat covers are thermal welded to the both ends of filter cartridge, fusing pleated membrane, inner core and outer cage together as an integrity. Flat cover thermal welding ensures no by pass.

6.End Cap Thermal Welding

End cap thermal welding is done by putting filter cartridge in the middle of End caps thermal welding machine, end caps on both ends. With set temperature, two end caps move forward to the middle and get in touch with flat cover. A few seconds later, end caps, pleated membrane and outer cage and inner cage are thermal welded together to form a complete pleated filter cartridge.

Contact: Jennifer

Phone: 0086-13797077685

E-mail: info@jdfiltration.com

Whatsapp:0086-13797077685

Add: