PVDF Filter Cartridges is made of a high porosity hydrophilic polyvinylidene fluoride membrane. It’s optimized for high retention efficiency, flow rate and long life time. The cartridges in order to reduce bio-burden and turbidity are highly compatible with the most rigorous sanitizing methods in the pharmaceutical industry. Also it’s available for other purpose of food & beverage, electronics, high purity chemical and various industrial applications. These 100% integrity tested cartridge filters are in compliance with FDA 21 CFR 177.1655.

Material:

Filter Medium: High porosity hydrophilic polyvinylidene fluoride membrane

Inner Core: Reinforced polypropylene, Stainless Steel

Outer Cage: Reinforced polypropylene

End caps: Reinforced polypropylene, PP with 316L SS insert

Gasket/O-rings: Silicon/Viton/NBR/EPDM

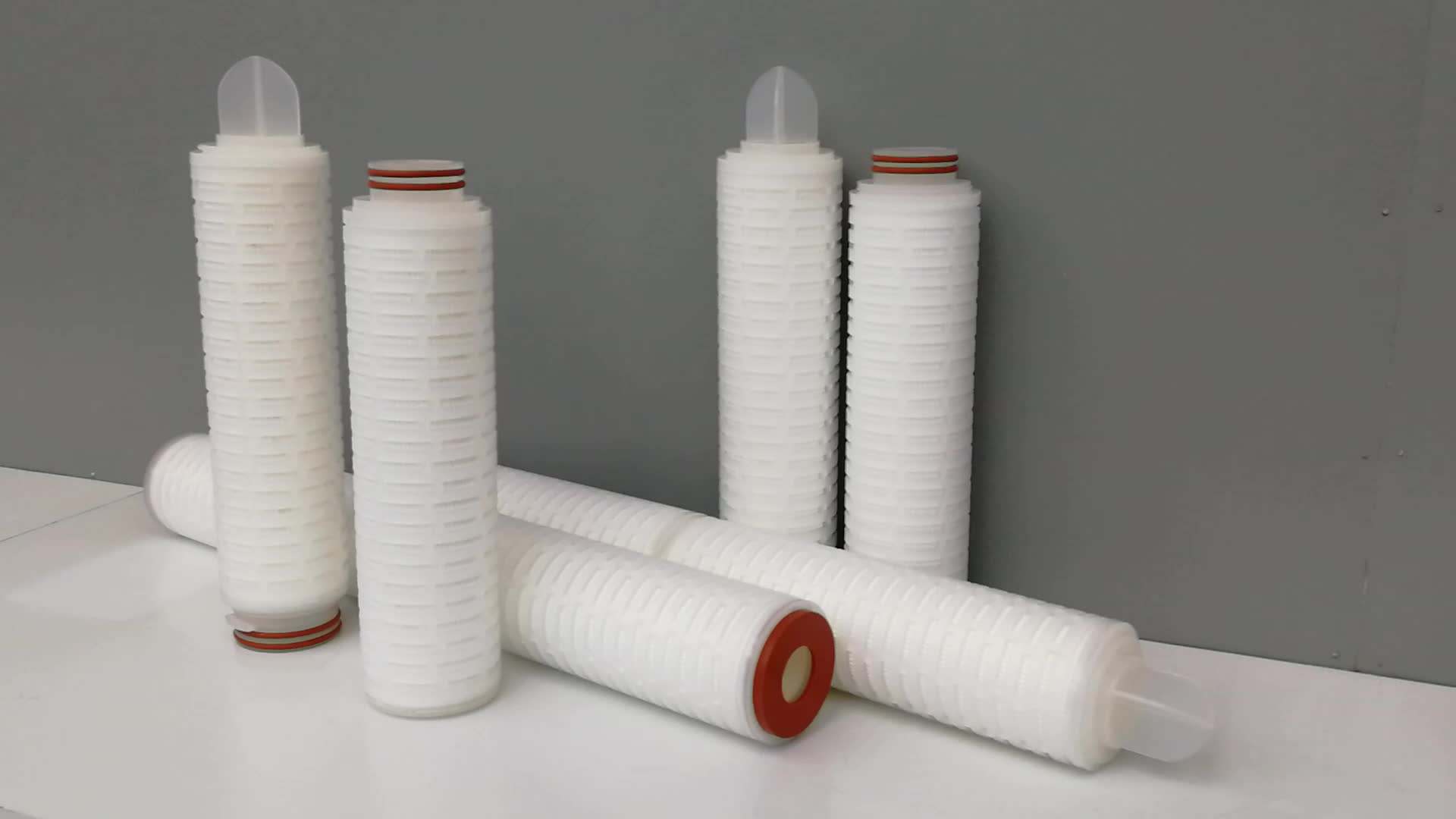

Dimension:

Outside Diameter: 2.7” (68mm)

Inner Diameter: 1.3” (33mm)

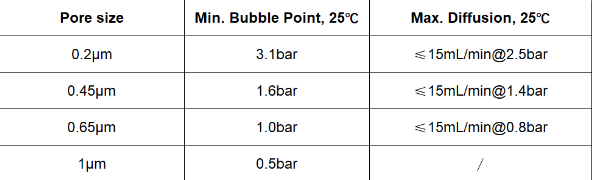

Micron Rating: 0.2μm, 0.45μm, 0.65μm, 1μm

Length: 5”, 10”, 20”, 30”, 40”

Effective Filtration Area: 0.65 m² / 10”

Operation condition:

Maximum Temperature: 1.7bar @ 80℃

Maximum Differential Pressure : 5.2bar @ 25℃ (forward)

Maximum Differential Pressure : 2.1bar @ 25℃ (reverse)

Sterilization:

Bacterial Endotoxin: ≤0.25EU/ml

Extractable: ≤20mg/10inch

Typical Applications:

Buffer, cell culture, downstream of the intermediate filtering

Protein purification

Food and beverage

High Purity Chemicals

Ultrapure Water

Electronics

Contact: Jennifer

Phone: 0086-13797077685

E-mail: info@jdfiltration.com

Whatsapp:0086-13797077685

Add: